The pressure on a pressure canner can be controlled in two ways:

- A dial gauge shows you what the pressure is, and you control the pressure using the stove burner knob to adjust the heat up and down as needed to raise or lower the pressure; OR

- Weighted-gauge (aka deadweight-gauge) releases any pressure above the desired amount of pressure.

[Ed: There’s a blended option: dual gauge. Discussion further down the page.]

A gauge measures pressure but cannot control pressure; a weight controls pressure but cannot measure it.

There are two types of pressure measuring gauges, a dial gauge and a weighted gauge. A dial gauge has a needle that moves along a numbered scale to indicate the pressure inside the canner. …… A weighted gauge fits over the air vent tube. It permits pressure in the canner to rise to the desired point and then releases excess steam by “jiggling” or “rocking” to keep the pressure from going higher.” [1] Fraser, Angela. Associate Professor/Food Safety Education Specialist. How Canning Preserves Food. Clemson University, Clemson, SC. Accessed March 2015 at https://www.foodsafetysite.com/consumers/resources/canning.html.

It’s important to have one way or the other to monitor or control the pressure and make sure it is high enough, because “processing foods at too low a pressure is a safety issue.” [2] Penn State Extension. Pressure Canning Dial Gauge Testing . 22 June 2012. Accessed January 2015 at https://extension.psu.edu/food/preservation/news/2012/pressure-canning-dial-gauge-testing

From a safety point of view, it’s okay to have too high a pressure. From a food product quality point of view, though, you really don’t want too high, either.

Dial Gauge

- Indicates pressure inside the canner;

- Must be checked regularly for accuracy;

- More flexibility in altitude adjustments – small psig increments;

- Has dead- or counter-weight to close open vent for pressurizing;

- Pressure is increased or decreased by adjusting burner heat. [3] Andress, Elizabeth L. Pressure Canning and Canning Low Acid Foods at Home. Cooperative Extension: University of Georgia. Powerpoint presentation, slide 17. Accessed March 2015 at https://nchfp.uga.edu/multimedia/slide_shows/CanLowAcid_web08.ppt.

If a dial gauge is inaccurate and the processing temperature is higher than recommended, the food inside the jar may be overcooked and softer in texture than desired. This is not a safety issue but is a quality issue. If the dial gauge tests off by less than 2 pounds, you will need to adjust the pounds pressure you use when processing the foods. If a gauge tests off by more than two pounds, the dial gauge should be replaced. Also, a gauge should be replaced if it is cracked or the glass covering is missing. …Pressure canners with a weighted gauge do not need to be tested for accuracy because they cannot go out of calibration.” [4] Penn State Extension. Pressure Canning Dial Gauge Testing . 22 June 2012. Accessed January 2015 at https://extension.psu.edu/food/preservation/news/2012/pressure-canning-dial-gauge-testing

Interesting factoid: Though the standard sea level dial gauge pressure is given as 11 lbs, the actual technical requirement is 10.5 lbs. But that fraction is too hard to practically monitor in a kitchen, so it’s rounded up to 11.

At sea level, a weighted gauge canner operated at 10 pounds pressure per square inch provides an internal temperature of 240°F. A dial gauge canner operated at sea level, however, must be operated at 10.5 pounds pressure to reach 240°F. We recommend operating dial gauge canners at 11 pounds pressure at sea level because it is easier to monitor this pressure on the gauge.” [5] Marilyn A. Swanson. Using and caring for your pressure canner. Pacific Northwest Extension. July 2013. PNW .421. Accessed March 2015 at https://www.cals.uidaho.edu/edcomm/pdf/PNW/PNW0421.pdf

A dial gauge pressure canner has a vent port which releases pressure or holds it in, using either a removable counterweight or a petcock that opens and closes to do so. This counterweight is not meant to move, jiggle or rock unless there is excessive pressure in the canner.

The 15# that comes with it is called a counter-weight and is there primarily for over-pressure safety purposes rather than actual weighing purposes (tho it is accurate for 15-16 lbs). [6] https://forums.gardenweb.com/discussions/1942198/weights-for-my-new-presto-23q-pressure-canner#6948797

The modern Presto dial gauge machines come with a 15 lb weight… that can act as a jiggler if you are at an altitude that requires that, but for anyone else, that “jiggler” gets referred to variously as a “counterweight”, “deadweight”, etc. Its purpose is to hold pressure in, not to let it out. (The weight can also be used if the canner is to be used as a pressure cooker.)

Dial gauges have small psig increments (1 lb increments) so they offer more flexibility when making altitude adjustments than do weighted gauges. For example, a person canning at an altitude of 3,000 feet, could choose 12 lbs on a dial gauge rather than having to use 15 lbs on a weighted gauge. This could prevent food from being slightly over processed. Dial gauges have a dead- or counter-weight used for closing a vent pipe when pressurizing the canner. This weight is not intended to indicate pressure. Pressure is regulated in a pressure canner by turning the heat up or down.” [7] National Center for Home Food Preservation Self Study Course. Module 4. Canning Low Acid Foods: Dial Gauge Canners. Accessed March 2015.

Note that All-American advises not to use its dial gauge for judging exact pressure with:

ALL AMERICAN pressure cooker canners are weighted-gauge canners. The pressure dial gauge is supplied as a reference only for when the unit is pressurized and timing for canning may roughly begin, or when the pressure has dropped to zero and the lid may be safely removed. The accuracy of your pressure dial gauge is +/- 2 pounds.” [8] Cooking & Canning with the All-American Pressure Cooker / Canner Manual. 2014. Page 11.

Testing Dial Gauges

The National Center says, “Dial gauges should be replaced if they test more than two pounds off…” [9] National Center for Home Food Preservation Self Study Course. Module 4. Canning Low Acid Foods: Storage, Replacement, and Testing. Accessed March 2015.

If your dial gauge reads high or low by more than 2 pounds when tested at 11 pounds of pressure, it should be replaced. If the reading is off by less than 2 pounds, (you can refer to compensation table) Low readings cause overprocessing. If a gauge is reading lower than it should, you can make adjustments to avoid overprocessing, but they are not essential to safety. Gauges that read high cause underprocessing and may result in unsafe food. Every pound of pressure is necessary to reach the canner temperature needed for producing safe food. [10] Marilyn A. Swanson. Using and caring for your pressure canner. Pacific Northwest Extension. July 2013. PNW .421. Accessed March 2015 at https://www.cals.uidaho.edu/edcomm/pdf/PNW/PNW0421.pdf

It’s getting more difficult to find a testing center even in the States, and outside of the States, most people wouldn’t even know where to begin looking.

The manufacturer of All-American canners says,

To test if the pressure dial gauge is functioning properly, compare the dial gauge to the regulator weight when heating the unit. If the gauge is within +/- 2 psi of what you have the regulator weight set at when it jiggles, the gauge is fine and doesn’t need to be replaced. If the gauge is more than +/- 2 psi of what the regulator weight is set at when it jiggles, the gauge should be replaced.” [11] Cooking & Canning with the All-American Pressure Cooker / Canner Manual. 2014. Page 11.

There are two methods for testing canner gauges. A maximum thermometer that registers and maintains the highest temperature reached inside the canner can be used. The thermometer is placed in a jar of water and is allowed to go through venting, a 10-minute process and a normal cool down period. A chart is used to determine the pounds of pressure that correspond to the reading on the thermometer. Maximum thermometers with a correct scale for this are hard to find today.

The preferred method of testing canner gauges uses a pump-type device to raise the pressure of the tester gauge. The canner gauge being tested should register the same pressure that shows on the tester gauge. Again, if the gauge is more than 2 lbs off, then the gauge should be replaced.” [12] National Center for Home Food Preservation Self Study Course. Module 4. Canning Low Acid Foods: Storage, Replacement, and Testing. Accessed March 2015.

Many people don’t want to go through the hassle of trying to get a gauge recalibrated every year. Even though some manufacturers will do it for you, some people worry that gauges could get knocked off balance by being banged around during shipping from the factory, so that they may arrive already malfunctioning. In fact, a few suggest getting your gauge tested already upon arrival at your house.

There is no value or logic in buying an expensive dial gauge [Ed; only] canner if you have no ability locally to have the dial tested for safety on a regular basis. [13]User posting from discussion thread in August 2009. https://www.backwoodshome.com/forum/vb/archive/index.php/t-16816.html

Dial gauges should be checked every year as well as after any mishap, such as being dropped, or after potential mishandling, such as after a household move.” [14] Griffith, Patti. Making Canning Work for You. University of Wyoming Cooperative Extension Service. MP-119-12. Accessed March 2015 at https://www.wyomingextension.org/agpubs/pubs/MP119_12.pdf

Some people say that “any radiator repair shop can test the gauge for you” [15] User post at https://www.homesteadingtoday.com/country-homemaking/preserving-harvest/369302-pressure-guage-pressure-canner.html but when you ask them for details, most are just quoting someone else and have no experience themselves. Occasionally you will see one or two people who’ve tried and have been sent packing.

Further reading: Pressure Gauge Testing.

Weighted Gauge

- Regulates pressure inside the canner;

- Open vent is the same one that pressure regulator fits;

- Will continue to allow some air to be released from canner during process;

- Don’t need to be tested for accuracy and in fact there is no way to test them;

- Altitude adjustment requires increase of 5 psig pressure. [16] Andress, Elizabeth L. Pressure Canning and Canning Low Acid Foods at Home. Cooperative Extension: University of Georgia. Powerpoint presentation, slide 18 to 19. Accessed March 2015 at https://nchfp.uga.edu/multimedia/slide_shows/CanLowAcid_web08.ppt.

The big disadvantage of weighted gauges is that people at altitudes above sea level may have to process their food products at more pressure than is actually needed. The USDA guides for weight gauges leap from 10 lbs to 15 lbs, with none of the 1 lb increments in between that they give for dial gauges.

The single disadvantage of weighted-gauge canners is that they cannot correct precisely for higher altitudes. At altitudes above 1,000 feet, they must be operated at canner pressures of 10 pounds per square inch instead of 5, or 15 pounds per square inch instead of 10.” [17] Swanson, Marilyn A. Using and caring for your pressure canner. Pacific Northwest Extension Publication. PNW 421. July 2010 revision. Accessed January 2015 at https://extension.oregonstate.edu/fch/sites/default/files/documents/pnw_421_usingcaringforyourpressurecooker.pdf

It is unclear why they recommend this: perhaps simply because canner manufacturers only made weights with that weight leap.

The weighted gauge is a small round weight or disk that is placed on the vent port to control internal pressure. Weighted-gauge pressure canners exhaust tiny amounts of air and steam each time the gauge rocks or jiggles during processing. They control pressure precisely and need neither constant watching nor checking for accuracy during processing. The sound of the weight rocking or jiggling indicates that the canner is maintaining the recommended pressure. The single disadvantage of weighted-gauge canners is that they cannot correct precisely for higher altitudes. At altitudes above 1,000 feet, they must be operated at canner pressures of 10 pounds per square inch instead of 5, or 15 pounds per square inch instead of 10.” [18] Marilyn A. Swanson. Using and caring for your pressure canner. Pacific Northwest Extension. July 2013. PNW .421. Accessed March 2015 at https://www.cals.uidaho.edu/edcomm/pdf/PNW/PNW0421.pdf

Weighted gauges being made are either one piece or several pieces. All-American and Mirro ones are one piece, with fitting holes for 5, 10 or 15 psig. The Presto is 3-piece, with the number of pieces used determining 5, 10 or 15 psig.

The Mirro weight will “jiggle” 3 to 4 times per minute. The Presto weight will rock gently throughout the entire process.

Don’t let the weight jiggle furiously. You are wasting energy, and run the risk of boiling the canner dry and losing your load of food.

You do not want to boil your pressure canner dry:

…potential damage results from boiling out the canning water too quickly. If a pressure canner goes dry, it almost certainly will warp. We here at USU know this for a fact during some of our research canning runs. A pressure canner ran dry for only a few minutes and the bottom warped so that it was no longer usable.” [19] Nummer, Brian A. Cook Surface Precautions for Home Canning. Utah State Cooperative Extension. FN/Food Preservation/2009-03. September 2009. Accessed March 2015 at https://extension.usu.edu/files/publications/publication/FN_Food_Peservation_2009-03.pdf

Weighted gauges do not require testing for accuracy. If the weight should get damaged, then it should be replaced. ” [20] National Center for Home Food Preservation Self Study Course. Module 4. Canning Low Acid Foods: Dial Gauge Canners. Accessed March 2015.

Note that the weight doesn’t measure pressure, it just releases excess pressure above a certain amount.

If at any time during processing the weight stops jiggling or moving as your brand indicates, then the canner must be brought back to the proper pressure, and processing time must be started over from the beginning. ” [21] National Center for Home Food Preservation Self Study Course. Module 4. Canning Low Acid Foods: Dial Gauge Canners. Accessed March 2015.

Dual Gauge

There’s also a third blended configuration possible, which is dual-gauge. All American canners are dual: both gauge and weight. Modern Presto canners are mostly shipped now as dial gauge but they can be converted into dual gauge with the purchase of an inexpensive set of weights.

Many people feel that it’s nice to have both the dial and the weight. The dial gives you a rough visual indication of how far you are away from achieving the desired pressure, and conversely, how far away from being completely depressurized at the end.

But, in terms of actual control of the processing, you ignore the dial. The weight is actually in control. The weight becomes authoritative.

The weights and the gauge don’t “work in conjunction”. The weights do the work, the gauge is just a back up check that may or may not be accurate. So buy the weight set and ignore the gauge. 😉 ” [22] https://forums.gardenweb.com/discussions/1942198/weights-for-my-new-presto-23q-pressure-canner#6948797

The All American ships with a 3-choice weight (5, 10, 15 pounds) and a gauge. For Presto, you purchase the 3-piece weight separately as an inexpensive add-on.

There is no problem with using the Presto models in this way. “…this is a new recommendation for buying the weight set. I recently contacted both Presto and Elizabeth Andress at the National Center for Home Food Preservation. Both said it was fine to use the weights.” [23]Linda Lou, Extension Agent Assistant. Garden web forum. November 15, 2007. Accessed March 2015 at https://forums.gardenweb.com/discussions/1976178/which-pressure-canner-should-i-buy#7253992

Some people feel that the weight can act as your gauge tester, too. “The added benefit is that with one of those, there’s no need to get the dial tested annually anymore. When the regulator moves, 11 lbs pressure has been reached. Then, look at the dial to see what it registers. It’ll either be showing 11 lbs or +/- by x number 11 lbs. Thus, the variance, if any, can be easily seen at home. (Low altitude canning.) My dial runs a hair over 11 lbs pressure when the 10 lb weight moves.” [24]User posting from discussion thread in August 2009. https://www.backwoodshome.com/forum/vb/archive/index.php/t-16816.html

Some people feel it’s easiest to learn pressure canning with a dual gauge machine:

IMHO, the best way to learn the rate is to watch the dial. That’s what I did when I first got mine. Once the canner came up to enough pressure to jiggle the regulator, I watched the reading on the dial as I adjusted the flame. (This was a trial run – no food in the canner.) Kept “playing” with it until I found the sweet spot that would give a slow steady rock that held the pressure where I wanted it.” [25]User posting from discussion thread in August 2009. https://www.backwoodshome.com/forum/vb/archive/index.php/t-16816.html

Gauge Pressure Versus Weight Pressure

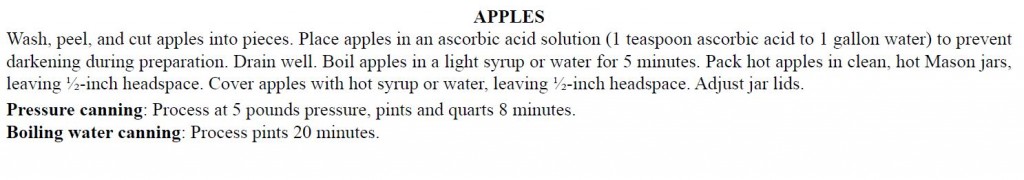

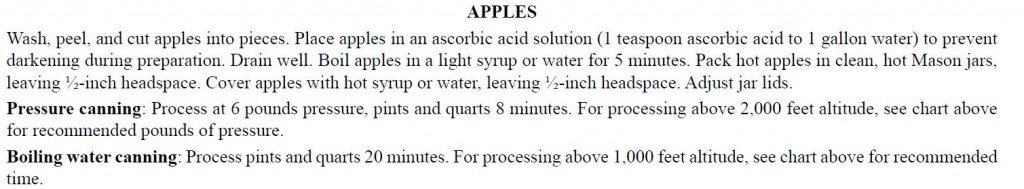

Notice the pressure difference in these exact same two recipes for apple. Weight says 5 pounds pressure; gauge says 6 pounds pressure.

Click to enlarge (Source: In: Presto Pressure Canner and Cooker, no gauge model, 01745 Manual. #72-720E. 2012. p 8.)

Click to enlarge. (Source: In: Presto Pressure Canner and Cooker, 23 quart model, #72-719F. 01781 Manual. 2012. p 8.)

You will almost always see gauge pressures as 1 pound more than weight pressures: 6 pounds for the gauge instead of 5 pounds for the weight, and 11 pounds for the gauge instead of 10 pounds for the weight.

This is because the actual pressure desired is slightly over 5 pounds and 10 pounds (i.e. 10.5 lbs.) The weight will release pressure when it’s slightly over that, indicating that slightly over that has been reached. For a dial gauge, the recipes round up the required pressure to the round numbers of 6 and 11, making them easier for people to see.

Why no weights between 10 and 15 lbs?

Many beginners often ask the question that older canners forget to ask: why are there no weights available in between 10 and 15 lbs?

We don’t know the answer, but it is a very good question: why, historically, did weighted gauge pressure canner makers decide to only offer 5, 10 and 15 lb weights, while other forms of pressure cookers / canners offer a weight such as 10.5, 11, 12, as well?

We don’t know but have put the question on the research list. It can’t be a matter of not “trusting the consumer” to select the right pressure, as that in fact already happens for dial gauges.

Some people take matters into their own hands by making the Presto 3-piece weight into a weight that covers weights between 10 and 15 pounds. The theory is to use the spindle with one of the 5 lb weight rings to give you 10 lbs, and then find a washer or a combination of washers that weighs ½ the weight of a 5 lb ring, and put those onto the spindle. To test your work, people then say to do a dry run or two canning just water to see if your gauge (if it’s properly regulated, presumably) confirms that the correct pressure is being achieved and regulated.

The above should not be construed as a recommendation or endorsement from healthycanning.com; this is just an FYI. We addressed the issue just in the interest of thoroughness because it is out there.

USDA directions on weighted gauge allow only a choice between 5 lb, 10 lb and 15 lb, and currently have no provision for pressure in between when pressure is regulated by a weight. We adhere to USDA guidelines and so support only those pressures.

Further reading

Penn State Extension. How Much Pressure — 10 or 11 pounds? 11 July 2012. Accessed January 2015 at https://extension.psu.edu/food/preservation/news/2012/how-much-pressure-10-or-11-pounds

References

Ally Armato

If I pressure canned at 10psi some beef chili but my canner said I was supposed to can at 11 because it’s a dial gauge- is that bad?

Paula Thompson

Your local extension service should be able to test your gauge.

Joan Black

I have a presto canner. Has the weight and a dail that tells pressure. I exhaust steam for ten minutes. Raise pressure to 10 lbs. have to lower heat so pressure doesn’t keep rising. When I do this the weight stops rocking. Will my food still be okay held at the 10 lbs pressure for the correct amount of time

Healthy Canning

The weight needs to rock slowly the entire time. It’s a question of learning how to adjust the heat dial on your stove for that particular burner.

Rachael Tryon

I have two older mirro pressure canners. They have the old weighted gauge on them where you select the lbs of pressure and drop it . Once processing is completed I remove from heat. It takes forever for pressure to go down. Sometimes 12 hours. I have heard people say this is bad on product but I also know I should not quick release either. I cannot get an answr to my question or even directed to a reliable source. Do I need to buy a new canner or what am I doing wrong? I’ve heard people talk about flat sour. If I’ve had that I guess we are used to it cause I’ve been canning this way for years. Thank you for any help.

Healthy Canning

12 hours, gosh. Please check with Presto’s excellent customer service to see what is up: https://www.gopresto.com/information/feedback.php

Rachael Tryon

Is mirro and presto the same?

Healthy Canning

Mirro is weighted-gauge only; Presto can be either dial gauge or weighted-gauge.

Melody Stankewycz

This site is very informative, thank you. I have pressure canned for many years without problems, however I recently tried something new and have doubt. I had a quantity of salmon and chicken to process and used quart jars instead of pint or half pint jars. I processed the fish at 10 lbs pressure for 240 minutes however I believe the elevation where I live is around 2,000 ft. I processed the chicken with the 10 lb gauge as well.. Will the food in these jars be adequately heated?

Healthy Canning

Regardless of jar size, I’m afraid the pressure wasn’t adequate, it should have been higher. https://www.healthycanning.com/altitude-adjustments-for-pressure-canning/

For processing times on salmon in quart jars, see the USDA Complete Guide, 2015 edition, page 5-11. ( https://nchfp.uga.edu/publications/usda/GUIDE05_HomeCan_rev0715.pdf )